NEMA L14-30P Wiring Diagram: How to Connect to a Power Meter

NEMA Wiring Schematic Manual for Electrical Experts

About seventy percent of the electrical breakdowns within establishments are due to poor wiring practices. This fact emphasizes the requirement of following recognized protocols, spotlighting NEMA wiring diagrams’ value for electrical specialists. Through these diagrams, wiring setups that satisfy both operational productivity and highest protection standards are presented.

The objective of this guide is to provide electrical practitioners with deep understanding into NEMA norms. Highlighting the significance of accurate electrical setups is essential. By mastering these principles, specialists can substantially cut the risk of accidents and ensure they adhere to safety protocols endorsed by Installation Parts Supply. Expertise in l 14 30 plug is crucial whether creating modern systems or fixing present ones, as it improves the capability to deliver safe and trustworthy electrical solutions.

Principal Conclusions

- NEMA wiring diagrams are vital for ensuring electrical security and conformity.

- Proper wiring techniques can decrease electrical issues significantly.

- Understanding NEMA norms enhances the effectiveness of electrical installations.

- Installation Parts Supply promotes adherence to safety protocols in electrical tasks.

- NEMA schematics support a wide range of applications across multiple sectors.

Comprehending NEMA Norms and Why They Matter

NEMA standards are essential in the electrical sector, guiding security and operation carefully. Crafted by the National Electrical Manufacturers Association, they set pivotal benchmarks for creating, examining, and identifying electrical gear. This ensures standardization and reliability across all electrical installations, which is of great value.

Which Are NEMA Norms?

NEMA designations span from levels 1 through 13. Every level defines the conditions necessary for electrical appliances to operate effectively. For example, NEMA 1 provides minimal indoor protection but is missing dust protection. On the other hand, NEMA 4 secures equipment is sealed, a necessity for withstanding considerable water immersion. Understanding these designations is essential in choosing suitable equipment.

How NEMA Norms Matter for Electrical Security

The role of NEMA standards in maintaining electrical security is significant. They play a significant part in lowering electric shock, device malfunctions, and fire dangers. Proper adherence to NEMA standards enables devices to function safely under specific ambient conditions. For open-air usage, NEMA 3 ratings provide protection against the weather, shielding the apparatus from harsh climate like rain and snow. In areas susceptible to explosions, standards including NEMA 7, 8, and 9 are essential for ensuring security.

Uses of NEMA Criteria in Wiring Drawings

The use of NEMA criteria in wiring diagrams is essential for safe, efficient electrical setups. These schematics utilize standardized symbols and formats based on NEMA classifications, streamlining the comprehension of complex electrical setups. This standardizing is helpful. It fosters transparency, uniformity, and reduces misinterpretations, and thereby boosting electrical protection across domestic and factory sectors.

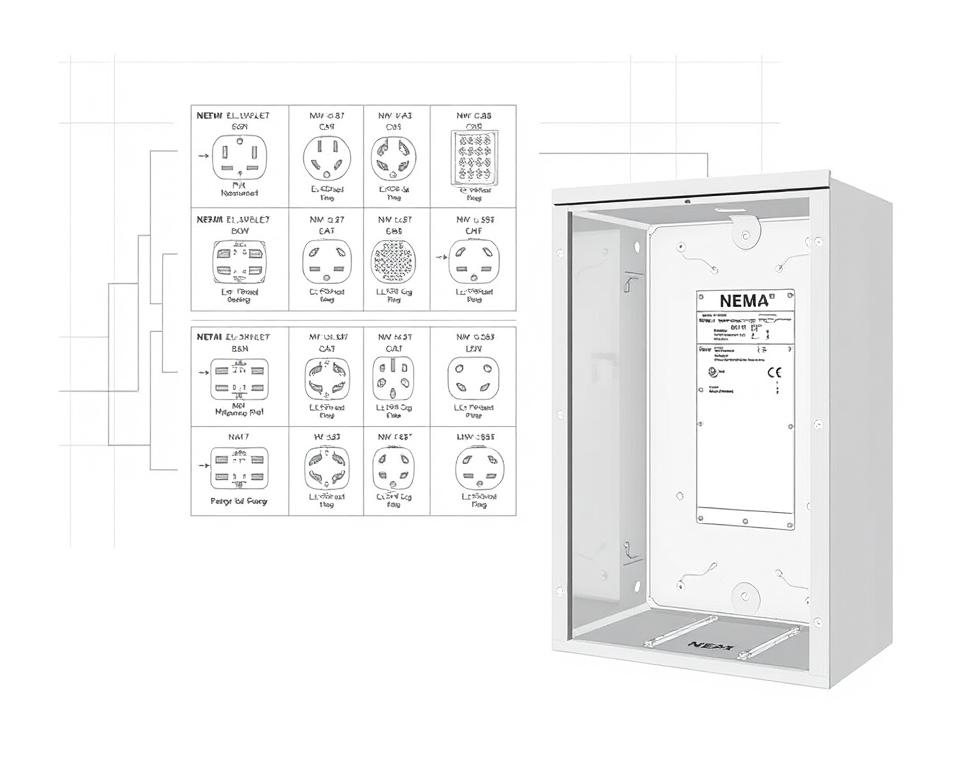

NEMA Wiring Diagram Essentials

NEMA wiring schematics are vital for electrical experts, ensuring complicated junctions transparent. They detail the junctions and components in different configurations. By understanding the components, categories, and symbols of NEMA diagrams, electricians can enhance their work in setups and upkeep.

Components of NEMA Wiring Diagrams

NEMA diagrams include crucial components for specific electrical configurations. You’ll find wiring connection points, couplers, and various fixtures for safe connections. Each piece secures energy is spread effectively, following safety guidelines.

Categories of NEMA Wiring Schematics

NEMA uses multiple drawings, like connection diagrams and circuit layouts. Such diagrams outline equipment relationships, while layouts illustrate power flow. Choosing the right schematic facilitates problem solving and setup.

Typical Symbols Employed in NEMA Wiring Drawings

Notations in wiring schematics are vital for clear communication. They illustrate toggles, loops, and connectors. Understanding these symbols assists crews comprehend drawings correctly. Thus, it guarantees setups adhere to NEMA standards.

NEMA Wiring Schematic Features

For electrical experts, grasping the fundamental aspects of accurate electrical wiring schematics is crucial. These diagrams offer both clarity and wholeness, synchronizing configurations with NEMA criteria. They necessitate precise marking and sizing to reduce deployment issues. This fosters a safer and optimal workplace.

Primary Characteristics of Precise Electrical Wiring Schematics

Accurate electrical wiring schematics are essential in electrical undertakings. They embody crucial attributes such as:

- Transparency: Schematics must be unambiguous, reducing misinterpretation risks.

- Completeness: They need to contain all key parts, connections, and electrical classifications.

- Conformance: Complying with NEMA norms is mandatory for securing protection and performance.

- Thorough Annotation: Clear markings on each element are crucial for grasping and avoiding mistakes.

- Accurate Proportions: The scales should reflect the true setup to depict the system accurately.

Understanding NEMA Connector Configuration

The insight into NEMA connector configuration is vital for making accurate linkages in electrical networks. Understanding of specific pin configurations upholds safety and equipment operation. There are a diversity of NEMA interfaces, designed for different power levels and currents, including:

| NEMA Connector Type | Current Rating | Voltage Rating |

|---|---|---|

| L5-15 | 15A | 125V |

| L5-20 | 20A | 125V |

| L14-20 | 20A | 125/250V |

| L1430C | 30A | 125/250V |

| L620C | 20A | 250V |

| L1430C | 30A | 125/250V |

| L630R | 30A | 250V |

Comprehending NEMA coupler configurations is essential for stable linkages, boosting performance. It’s paramount to align interfaces with devices properly using rotary-lock or linear blade types, to prevent hazards.

NEMA Device Wiring

NEMA appliance wiring includes multiple configurations for safe electrical appliance interfaces. These standards ensure that equipment integrate safely, minimizing risk. Grasping the different NEMA appliances and their wiring is essential for electricians.

Different Types of NEMA Units

NEMA organizes appliances by category based on voltage levels and amperage demands. Primary arrangements are:

- 2-Pole, 2-Wire

- 2-Pole 3-Wire Grounding

- 3-Pole 3-Wire

- 3-Pole, 4-Wire with Grounding

- 4-Pole, 4-Wire

- 4-Pole 5-Wire Grounding

These setups find use in homes and industrial facilities, supporting 125V, 208V, and 480V.

NEMA Plug Wiring Explained

NEMA plug wiring varies to suit various power needs, with locking types ensuring consistent interfaces in unstable environments. For instance, the L5-15 plug operates at 15 amps, frequently used in business sites, whereas the L14-20 is designed for 20 A at 125/250 V.

The NEMA designation system helps in choosing the correct plugs, emphasizing attributes like electrical polarity and connection to ground. Such accuracy guarantees that appliances operate securely.

NEMA Outlet Wiring Guidelines

Proper wiring of NEMA sockets aligns with electrical codes and safety guidelines. For instance, L530R receptacles are rated for 30 A at 125 voltage, with L630R models for 250 voltage. Proper grounding is essential to dodge electrical mishaps.

Selecting certified NEMA plugs and sockets ensures protected, regulation-compliant configurations. It’s vital to check authoritative protocols when implementing.

NEMA Motor Wiring and Applications

NEMA motor wiring is essential in electrical engineering, notably for manufacturing use. Grasping how NEMA motor arrangement works secures that machines are set up for optimal performance. Such devices, like single-phase and three-phase models, require accurate wiring to operate securely and efficiently.

Overview of NEMA Motor Wiring

Grasping NEMA motor wiring necessitates knowledge of junctions and configurations. Nearly all three-phase motors now support dual-voltage, signifying they can operate at both low (208-230V) and high voltage levels (460V). Wiring at high voltage makes a motor use less current than at low voltage. High voltage advantages encompass thinner cables for the input, a major benefit for motors over 10 HP.

While both NEMA and IEC units are utilized in the market, NEMA variants are usually larger and more costly than IEC ones for less than 100 HP applications. NEMA starters range from size 00 to 9, suitable for multiple uses. A common characteristic in NEMA starters is a Fault Class of 20, engineered to activate when a motor’s amperage exceeds 6x the Full Load Amperage in 10 secs.

Choosing the Correct NEMA Motor Configuration

Selecting the correct NEMA motor setup impacts overall operation and protection. A common three-wire control circuit utilizes three wires for a start/stop pushbutton panel, allowing direct motor management. Common three-phase configurations include the 12 Lead Dual Voltage and 6 Lead, enabling Wye and Delta arrangements.

IEC motor starters commonly feature phase loss detection, increasing safety. They also offer configurable Fault Classes for customized protection in low voltage operations. Furthermore, many models have temperature safeguards, vital for one-phase and Dual Voltage systems.

| Arrangement | Voltage Type | Current Specification | Common Application |

|---|---|---|---|

| 12 Lead Dual Voltage | Dual Voltage (208-230V / 460V) | Varies by motor size | Applications with Wye Start and Delta Run |

| 6 Lead | Single/Dual Voltage | 32 amps maximum | Wye or Delta connections |

| Single Phase | Single Voltage | Dependent on adjustment (1-5A) | Applications with Two Speed, Two Winding |

| Delta Connection | High-Power Voltage | Based on configuration | Various applications including Current Transformers |

To Conclude

Comprehending NEMA wiring schematics and standards is vital for electrical specialists aiming to enhance their capabilities and follow electrical safety norms. These standards guarantee protected and efficient electrical setups but also prevent hazards stemming from incorrect wiring. In summary, adhering to NEMA standards leads to the augmented capability of multiple NEMA devices and configurations.

For electricians, the availability of high-quality supplies can profoundly influence the result of their work. Installation Parts Supply offers a extensive range of wiring items aligned with NEMA standards. This allows specialists to obtain vital elements for fulfilling these key regulations. Superior materials and deep understanding of NEMA wiring diagrams significantly elevate installation safety and effectiveness.

During electrical setups, always prioritize safety and precision above all. Mastering NEMA standards delivers the knowledge needed for applying best practices accurately. This guarantees that each electrical connection established aligns with high-quality standards.

Frequently Asked Questions

Which are NEMA wiring diagrams?

NEMA wiring schematics showcase the arrangements and connections of NEMA-standard electrical appliances. They adhere to safety and functional criteria established by the National Electrical Manufacturers Association.

How are NEMA criteria vital for electrical safety?

NEMA standards are essential to setting safety and operational benchmarks for electrical devices. These principles enable electrical experts lower electrocution risks, device malfunctions, and fire risk.

Identify the key parts are essential in a NEMA wiring diagram?

Key elements in a NEMA wiring drawing comprise circuit setups and linkage diagrams. These diagrams also feature thorough annotations and depict the electrical system’s diverse parts precisely for setups.

What types of NEMA wiring diagrams are used?

Multiple NEMA wiring drawings address various applications, including circuitry for power distribution and component interconnection schematics. Every design fulfills a specific role in electrical setups.

Which are the typical symbols found in NEMA wiring schematics?

Typical symbols in these drawings represent switches, fuses, sockets, and other elements. Utilization of these symbols facilitates unambiguous communication and precise interpretation of wiring drawings.

Which are the key characteristics of correct electrical wiring schematics?

Accuracy in electrical wiring diagrams is marked by their transparency, thoroughness, and detailed marking. They need to meet NEMA norms to avoid mistakes in installation.

What is a NEMA connector layout?

A NEMA connector configuration describes electrical linkages at a connector, showing distinct pin functions. This ensures secure and efficient junctions in electrical systems.

Identify the different kinds of NEMA devices?

NEMA appliances consist of various electrical sockets and connectors, like adapters and outlets. They are engineered for various ampere and power requirements to meet unique operational demands.

How is NEMA plug wiring configured?

NEMA plug wiring is determined by particular amperage and voltage levels needs, adhering to security protocols and electrical codes for various electrical setups.

Identify the recommendations are there for NEMA receptacle wiring?

Guidelines for wiring NEMA receptacles stress adhering to electrical codes, ensuring correct electrical polarity, and picking correct wire sizes. This ensures both protection and operation in electrical installations.

What is the method to wire a NEMA motor effectively?

To wire a NEMA motor, one must comprehend its particular one-phase or tri-phase configuration. Opting for the right wiring technique is crucial, in addition to observing electrical security for maximum motor performance.

Which factors should be considered when selecting a NEMA motor configuration?

Choosing a NEMA motor arrangement demands an evaluation of the application’s energy requirements and operational characteristics. It’s also crucial to verify suitability with pre-existing systems for reliable efficiency and protection.